Product Details

Product Introduction

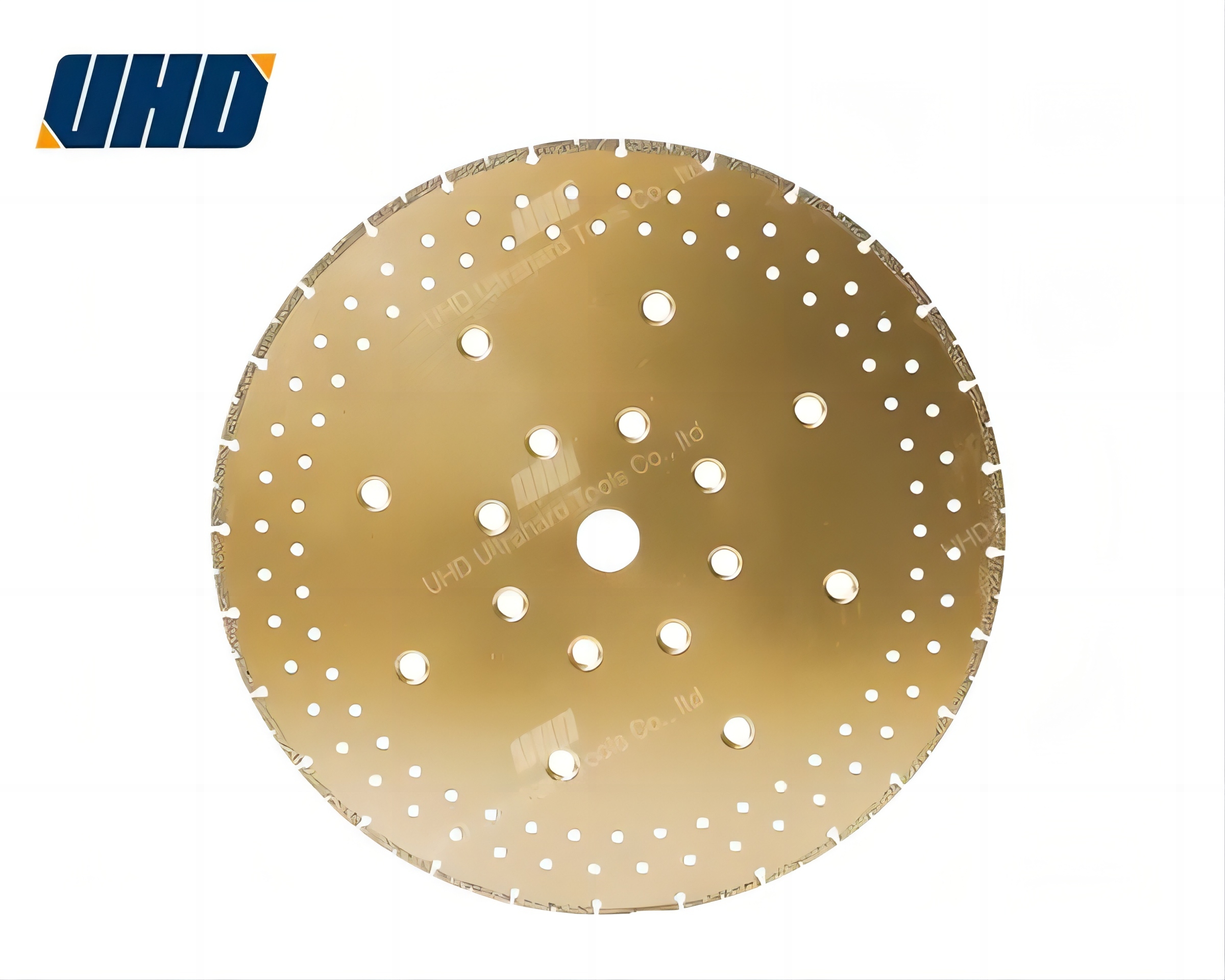

UHD Superhard Material Tools Co., Ltd. specializes in developing and producing ultra-high-performance vacuum-brazed diamond cutting tools tailored for the metalworking and stone cutting industries. Suitable for industrial environments ranging from 0°C to 120°C, these tools utilize advanced vacuum brazing technology to effectively enhance tool durability and cutting precision. Their innovative design ensures excellent cutting efficiency, significantly reducing equipment downtime and helping customers improve overall production efficiency. Products can be customized to meet diverse application needs based on different mechanical interfaces and process requirements. As an industry-leading high-tech enterprise, UHD relies on its strong R&D capabilities and strict quality management system to provide comprehensive cutting solutions that meet international standards, earning the trust of customers worldwide. Choosing UHD diamond cutting tools means you'll enjoy professional technical support and efficient after-sales service to help your projects achieve outstanding results.

Advantages and features

1. Using advanced vacuum brazing technology to ensure the solid bonding of diamond grains, improving durability and cutting life.

2. Excellent high and low temperature adaptability, suitable for industrial environments from 0°C to 120°C, ensuring cutting stability.

3. High cutting efficiency, significantly reducing equipment downtime and improving production efficiency.

4. Diversified customization capabilities, compatible with different mechanical interfaces and processing requirements.

5. Strict quality management and international standard certification ensure product quality and safety.

6. High-quality after-sales service and professional technical support are provided to help customers successfully complete processing tasks.

Application Scenario

This machine is suitable for metal processing, stone cutting, and related manufacturing industries, particularly for industrial users with high demands for cutting precision and efficiency. It is widely used in mold manufacturing, building and decorative material processing, precision parts production, and mineral resource development. Target customers include large-scale manufacturers, precision processing plants, construction engineering companies, and equipment maintenance service providers. It is particularly suitable for those who need to reduce production downtime and improve processing quality.