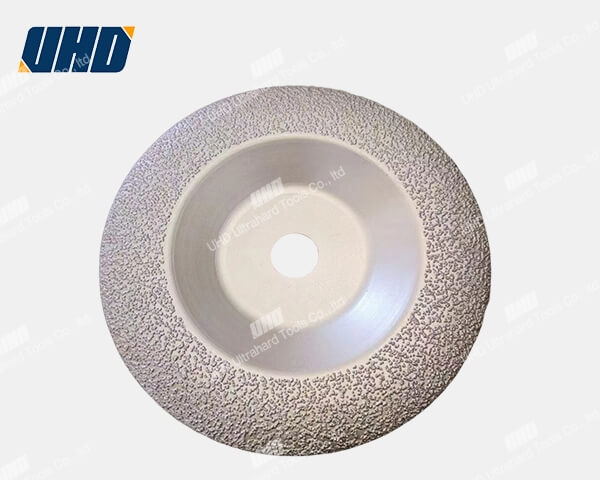

Product Details

Product Introduction

Henan UHD Superhard Tools Co., Ltd. specializes in the R&D and manufacturing of brazed diamond grinding wheels. Utilizing advanced brazing technology combined with high-quality diamond particles, these wheels are specifically designed for the high-intensity grinding needs of gray cast iron castings. Wheel sizes range from 100 to 180 mm, supporting customized flat and curved shapes to meet diverse machining scenarios. The products boast excellent wear resistance and impact resistance, significantly extending service life, improving machining efficiency, and ensuring safe and stable operation. UHD adheres to strict production standards based on the ISO 9001 quality management system, upholding the philosophy of providing high-performance brazed grinding tools to global industrial customers. We support personalized customization and technical consultation, helping customers maximize equipment value and achieve superior process quality. Our brazed diamond grinding wheels are widely used in the processing of materials such as metals, ceramics, glass, and cemented carbide, making them an ideal choice for industrial-grade high-intensity grinding.

Advantages and features

1. Utilizing cutting-edge brazing technology combined with high-quality diamond particles, it achieves an ultra-long service life and stable performance.

2. Multiple sizes (100-180mm) and various flat/curved surface options to meet different process requirements.

3. Excellent wear resistance and impact resistance, adaptable to high-intensity grinding environments, and improved processing efficiency.

4. Strictly implement the ISO 9001 quality management system to ensure product quality and consistency.

5. Supports personalized customization services for global customers, flexibly meeting various complex processing applications.

6. Comprehensive technical support and after-sales service to help customers continuously improve production efficiency.

Application Scenario

This product is primarily used for high-strength grinding of gray cast iron parts, suitable for industries such as automotive manufacturing, mechanical engineering, and hardware tool manufacturing. It can also be widely used for the precision machining and finishing of glass, ceramics, and cemented carbide materials. Target customers include metal processing plants, mold manufacturing companies, precision manufacturing plants, and research institutions, and it is especially suitable for industrial users requiring high wear resistance, high efficiency, and customized brazed grinding tools.

.png?x-oss-process=image/resize,m_fill,h_300,w_300/format,webp)