As an industrial client in the international market, you're no stranger to the challenges posed by the sudden failure of diamond grinding wheels. These failures can lead to production line shutdowns, resulting in significant efficiency losses and cost overruns. Let's start with a real - world example. In a gray cast iron machining plant, a grinding wheel fracture during the operation brought the entire production line to a halt for several hours. This not only wasted raw materials but also caused delays in order fulfillment, leading to dissatisfied customers and potential financial losses.

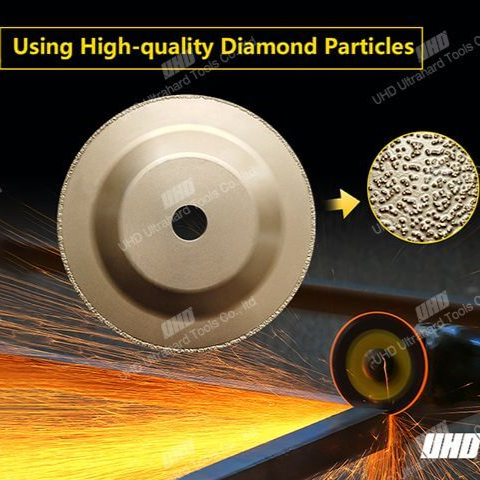

The state of abrasive grains is a crucial indicator of the grinding wheel's condition. When abrasive grains start to fall off, the grinding efficiency decreases significantly. For example, in a well - maintained grinding wheel, the abrasive grains are firmly attached, as shown in Figure 1. In contrast, a worn - out wheel will have visible gaps where grains have fallen out. This can lead to uneven grinding and poor surface finish of the workpiece.

Monitoring the grinding force is another important aspect. As the grinding wheel wears, the grinding force tends to increase. A sudden spike in grinding force may indicate that the wheel is no longer functioning optimally. For instance, if the normal grinding force in a specific process is around 500N, and it suddenly jumps to 700N, it's a red flag. You can use a grinding force sensor to track these changes over time.

Abnormal surface temperature rise is also a sign of potential problems. Excessive heat can cause the bonding material of the grinding wheel to weaken, leading to premature failure. A normal surface temperature during grinding should be within a certain range, say 50 - 80°C. If the temperature exceeds 100°C, it's time to investigate further.

.png)

To keep your diamond grinding wheel in good condition, here are some easy - to - follow daily maintenance steps:

After each use, clean the grinding wheel with a soft brush to remove debris. You can use a mild cleaning agent if necessary. First, turn off the power and let the wheel cool down. Then, gently brush the surface in a circular motion. Rinse with clean water and dry it thoroughly.

Apply a thin layer of anti - rust oil to the metal parts of the grinding wheel. This can prevent corrosion, especially in a humid environment. Use a clean cloth to apply the oil evenly.

Store the grinding wheel in a dry and cool place. It's best to keep it in a protective case to prevent physical damage. Avoid stacking heavy objects on top of it.

We've designed a 'Three - Step Diagnostic Method' to help you quickly decide whether to replace the grinding wheel:

By following these steps, you can make informed decisions and avoid unexpected failures.

Engineers' experience: Regularly checking the grinding wheel based on these methods can save up to 30% of the replacement cost and increase the overall production efficiency by 20%.

Are you ready to take control of your diamond grinding wheel's lifespan? Click here to download our free PDF self - check list or contact our UHD technical support team to get a customized grinding wheel lifecycle solution. Don't let unexpected failures disrupt your production line again!