In the world of precision manufacturing, where every micron counts and production schedules demand unwavering efficiency, the choice of diamond grinding discs can make or break your operations. I've witnessed countless manufacturing facilities struggle with suboptimal grinding performance, watching as precious production hours slip away due to frequent disc changes, inconsistent surface finishes, and premature tool wear.

Consider this: A mid-sized ceramic manufacturer was experiencing 27% downtime due to grinding disc replacements and quality issues. Their reject rate hovered around 8%, costing them approximately $42,000 annually in wasted materials alone. After implementing a strategic diamond disc selection process, they reduced downtime by 63% and cut reject rates to 2.3% within three months.

"We were changing discs every 4 hours and still getting inconsistent results. The五步选型法 completely transformed our production line—now we're running 12-hour shifts with the same disc and achieving uniform finishes across all our ceramic components."

— Manufacturing Engineer, Automotive Components Supplier

Your grinding disc must complement the material you're working with. For granite and other natural stones, a metal-bonded disc with 30/40 mesh diamond grit delivers optimal stock removal. When processing glass or ceramics, consider resin-bonded discs with finer grit sizes (120/140 mesh) to prevent surface micro-cracking.

Hardened steel and carbide require specialized brazed diamond technology that maintains consistent cutting edges under extreme heat and pressure. The wrong bond type can reduce disc life by up to 70% and compromise surface integrity.

The relationship between grit size and surface finish is exponential. Coarse grit (30-60 mesh) removes material rapidly but leaves Ra values of 2.5-5.0 μm, while ultra-fine grit (325-400 mesh) produces mirror-like finishes below 0.2 μm but at a significantly slower material removal rate.

| Grit Size | Typical Application | Surface Finish (Ra) | Material Removal Rate |

|---|---|---|---|

| 30/40 | Heavy stock removal | 3.5-5.0 μm | Very High |

| 80/100 | General purpose grinding | 1.5-2.5 μm | High |

| 180/220 | Precision finishing | 0.8-1.5 μm | Medium |

| 325/400 | Mirror finishing | <0.2 μm | Low |

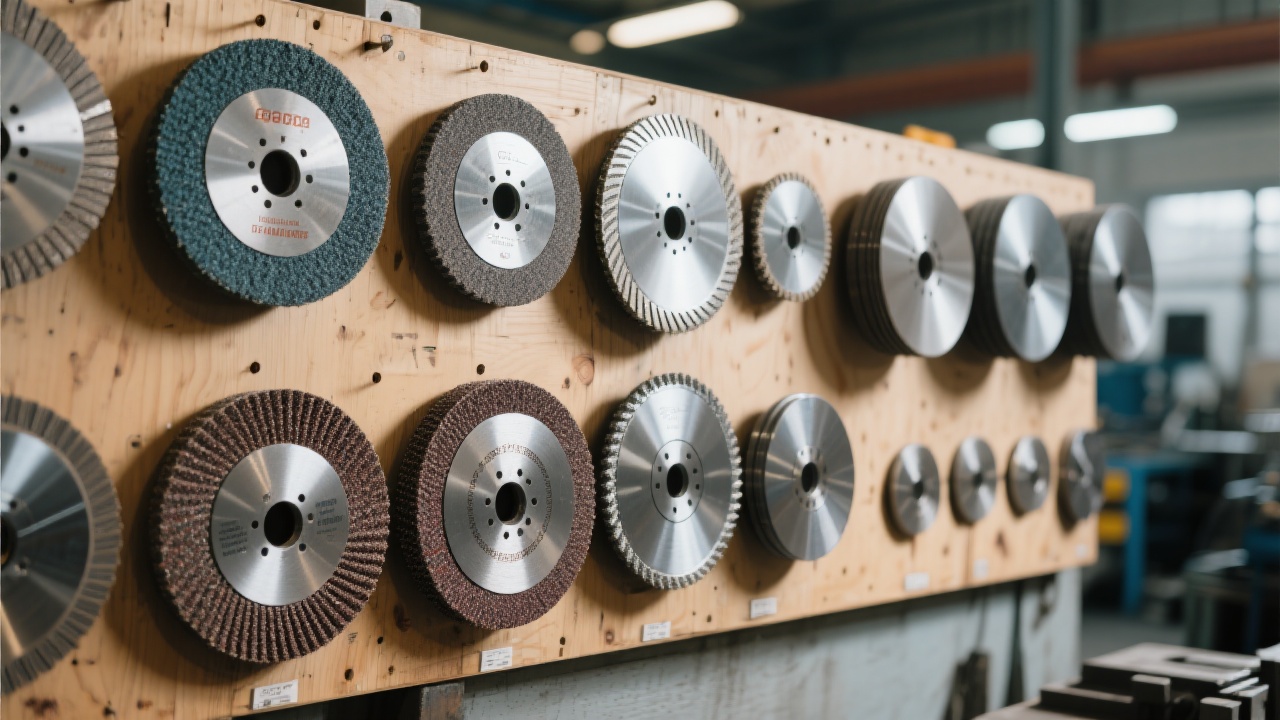

Flat discs work exceptionally well for planar surfaces, but when dealing with complex curved components, specialized contour discs reduce cycle times by up to 40%. The key advantage of curved discs lies in their optimized heat dissipation design—preventing thermal damage to sensitive materials while maintaining consistent cutting pressure across the entire contact area.

For internal diameters and concave surfaces, cup-style discs with undercut protection prevent workpiece damage and ensure uniform material removal. When selecting disc diameter, remember this rule of thumb: disc diameter should be 3-5 times the workpiece thickness for optimal stability and cutting efficiency.

Metal bonds excel in heavy-duty applications, offering 30-50% longer life than resin bonds but requiring higher spindle power. Resin bonds provide superior surface finishes and work well with heat-sensitive materials. For ceramic matrix composites and other advanced materials, hybrid bonds combining metal and resin technologies deliver the best of both worlds.

Advanced brazed diamond technology has revolutionized precision grinding, with diamond retention strength increased by over 200% compared to traditional electroplated discs. This translates to fewer dressing cycles and more consistent performance throughout the disc's lifespan.

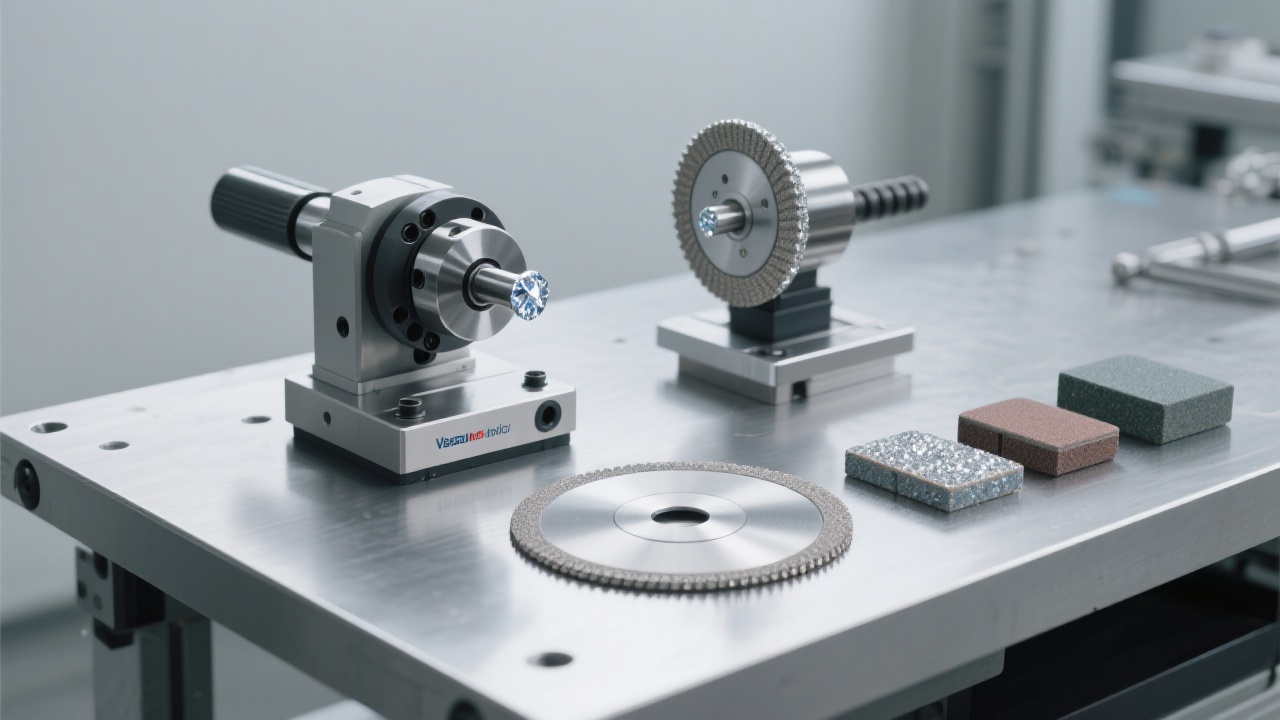

A leading aerospace parts manufacturer was struggling with inconsistent results when grinding titanium alloy turbine components. Their existing discs required replacement every 180 parts, with significant variation in surface finish.

By implementing the五步选型法, they identified that their application required a 125mm diameter brazed diamond disc with 120/140 grit and a specialized metal-ceramic bond. The results were remarkable:

Annual savings exceeded $145,000, with additional quality-related savings estimated at $82,000.

Selecting the optimal diamond grinding disc isn't guesswork—it's a systematic process that considers your material properties, desired finish, production volume, and equipment capabilities. The五步选型法 guides you through this decision with precision, helping you avoid the costly trial-and-error approach that plagues many manufacturing operations.

When you get the selection right, the benefits extend beyond longer disc life and better surface finishes. You'll experience fewer machine adjustments, reduced operator fatigue, lower energy consumption, and ultimately, a more competitive position in your market.

UHD磨盘已助力超百家工厂实现工艺升级

Download Your Free Diamond Disc Selection GuideComplete with material compatibility charts, grit selection tool, and troubleshooting guide

Remember, in precision manufacturing, your grinding disc is more than just a tool—it's a critical component of your quality control system and production efficiency strategy. By taking the time to understand and apply these selection principles, you'll position your operation for greater success in an increasingly competitive global marketplace.