Is your hard material processing operation struggling with low efficiency and premature disc wear? You're not alone. According to industry research, improper disc selection can reduce production efficiency by up to 35% and increase tooling costs by 40%. The good news is that with the right knowledge, you can transform your grinding process from a source of frustration into a competitive advantage.

Critical Consequence Alert:

A leading stone processing facility recently reported reducing their grinding time by 28% and extending disc life by 52% after implementing proper diamond disc selection techniques. The difference came down to understanding how diameter, grit size, and bond type interact with specific materials.

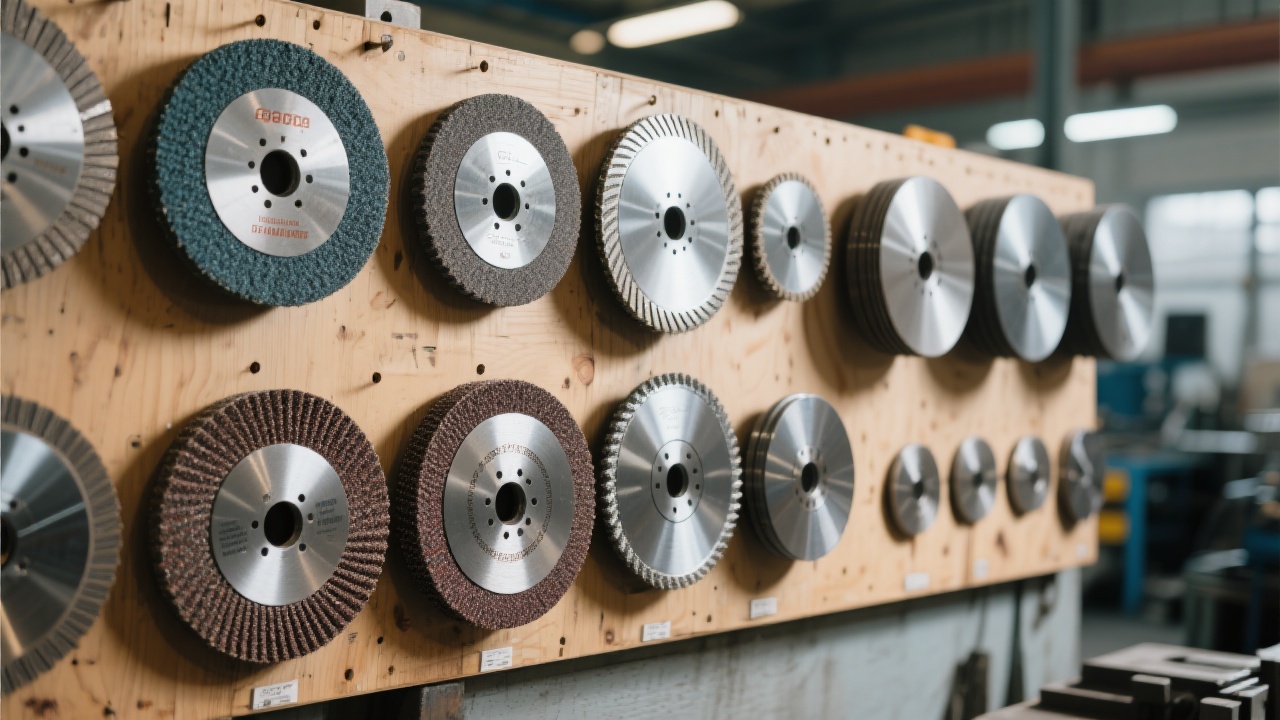

Selecting the optimal diamond grinding disc isn't about finding the most expensive option—it's about finding the right match for your specific application. Let's break down the four critical factors that will transform your grinding results:

The relationship between disc diameter and machine capacity directly impacts both safety and performance. A disc that's too large for your equipment creates dangerous vibration and uneven wear, while an undersized disc leads to inefficient material removal and extended processing times.

As a general guideline, maintain a 10-15% clearance between the disc diameter and machine guard. For example, a 200mm disc works optimally with machines rated for 225-230mm maximum disc size.

Diamond grit size determines both material removal rate and surface quality. Coarse grits (30-60 mesh) remove material quickly but leave a rough surface, while fine grits (200-400 mesh) produce superior finishes with slower material removal.

| Grit Size | Application | Material Removal Rate | Surface Finish |

|---|---|---|---|

| 30-60 | Heavy stock removal, rough grinding | High | Rough (Ra 5-10μm) |

| 80-120 | General purpose grinding | Medium | Moderate (Ra 2-5μm) |

| 150-200 | Semi-finishing operations | Moderate-Low | Smooth (Ra 0.8-2μm) |

| 220-400 | Fine finishing, polishing | Low | Mirror-like (Ra <0.8μm) |

The bond material holds diamonds in place and controls their exposure during grinding. Choosing the right bond directly impacts disc life and performance:

Exceptional for hard, brittle materials like granite and carbide. Offers 30-40% longer life than resin bonds but requires higher machine power. Ideal for dry grinding applications where heat resistance is critical.

Provides superior surface finish on glass, ceramics, and marble. Self-sharpening特性 maintains consistent performance. Best suited for wet grinding applications where cooling is available.

"After struggling with constant disc changes and inconsistent finishes on our ceramic bathroom fixtures, we implemented the selection methodology outlined in this guide. The results were remarkable—we reduced disc consumption by 43% and customer complaints about surface quality dropped to zero."

— Manufacturing Director, European Ceramic Producer

For granite and marble processing, we recommend a 180mm metal bond disc with 80-120 grit for initial shaping, followed by a 220 grit resin bond disc for finishing. This combination typically increases production by 22% while reducing chipping by up to 65% compared to using a single disc type.

When working with stainless steel, heat management is critical. A 150mm resin bond disc with 120-150 grit, used with proper coolant, reduces heat discoloration by 90% while achieving the required Ra 1.6 finish. Many manufacturers report tool life improvements of 35% by following this specification.

Ceramic components with complex geometries require specialized disc designs. Our segmented diamond discs with 150-200 grit resin bonds have helped manufacturers reduce breakage rates by 58% while maintaining tight tolerances of ±0.02mm.

Selecting the right diamond grinding disc isn't just about replacing a tool—it's about optimizing your entire production process. With the right selection strategy, you can expect:

Our comprehensive toolkit includes the exclusive 5-Step Selection Method and detailed Grit Size Comparison Chart used by industry leaders to optimize their grinding processes.

Download Your Free Toolkit NowTransform your grinding process with UHD diamond discs—where every revolution delivers precision, efficiency, and lasting performance.

Remember, the difference between average and exceptional grinding results lies in the details of proper disc selection. By matching diameter, grit size, and bond type to your specific material and application requirements, you'll not only improve product quality but also significantly reduce production costs. The most successful manufacturers understand that their choice of grinding tools directly impacts their bottom line and competitive position in the market.