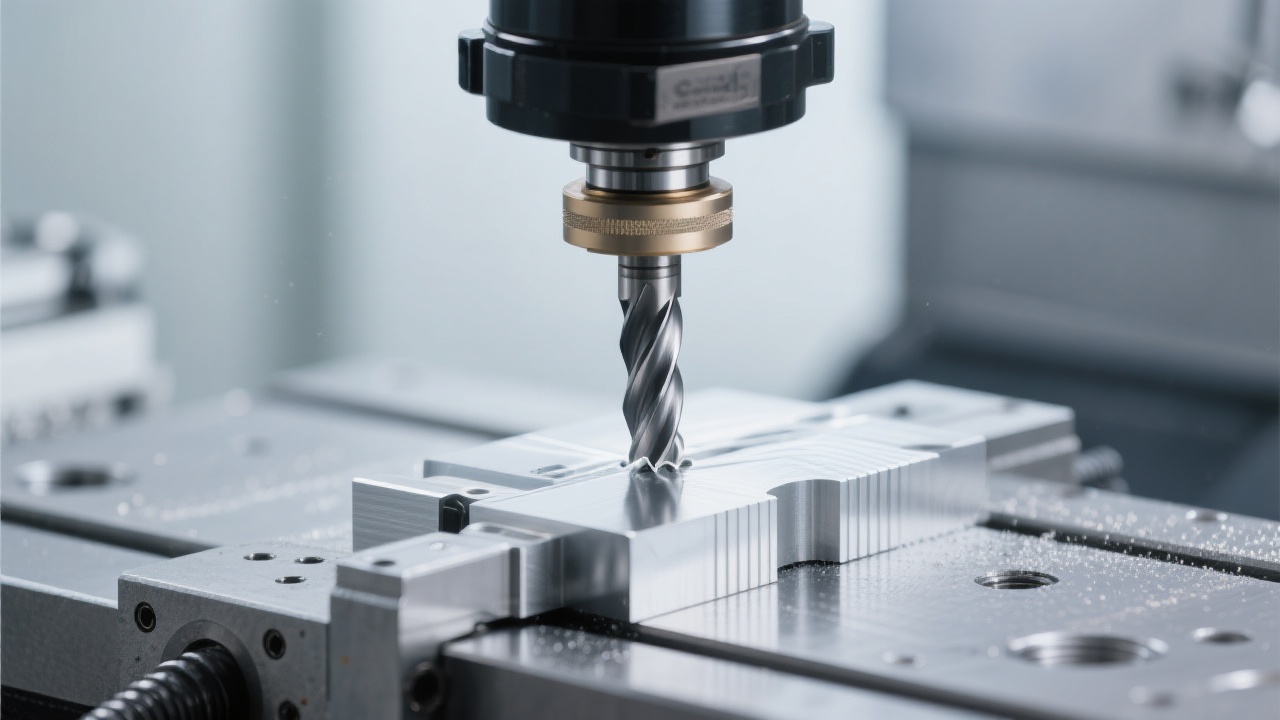

The industrial grinding landscape has been revolutionized by brazed diamond grinding wheels, which offer unparalleled durability and impact resistance. UHD Company’s state-of-the-art manufacturing process, underpinned by rigorous ISO 9001 standards, exemplifies how combining high-purity diamond particles with precision brazing techniques can drive superior performance in high-intensity grinding applications.

Central to the durability of brazed diamond grinding wheels is the quality of diamond abrasives used. UHD sources ultra-high-purity diamond grit, boasting 99.9% purity and a controlled particle size distribution between 30–50 microns. This precise selection minimizes micro-fractures and optimizes cutting efficiency, delivering consistent abrasive action essential for machining tough materials like gray cast iron, ceramics, glass, and hard alloys.

The brazing process ranks as a critical determinant of wheel integrity. UHD employs advanced thermal profiling within a vacuum brazing furnace, maintaining temperature gradients between 850°C and 900°C to ensure a uniform molten filler metal flow. Stringent interface bonding strength tests routinely exceed 45 MPa, assuring robust adhesion between diamond particles and metallic matrix. Such precision thermal control mitigates thermal stress and preserves abrasive longevity.

Industry Highlight: According to ISO 9001 compliance reports from UHD, over 98% of their brazed wheels pass quality audits with negligible particle shedding after 100 hours of continuous gray cast iron grinding tests.

UHD’s dedication to ISO 9001 quality management manifests in end-to-end process tracking, rigorous batch inspections, and statistical process controls. This systemized approach results in tight tolerances for concentricity (± 0.02 mm) and surface finish quality (Ra ≤ 0.4 μm), crucial for grinding precision components with minimal tool wear and vibration. Performance stability translates directly into predictable operational costs and reduced machine downtime.

Gray cast iron machining presents formidable challenges due to its abrasive graphite flakes and brittleness. UHD’s brazed diamond wheels exhibit outstanding resistance to abrasive wear and impact chipping, demonstrated in both flat surface and complex curved component grinding. In field trials, customers recorded a 25% increase in wheel life and a 15% improvement in surface finish quality compared to conventional grinding wheels.

Recognizing diverse industrial demands, UHD offers tailored grinding wheel configurations—varying grit size, bond composition, and wheel geometry—for specific machining goals. Their technical team provides on-site and virtual consulting to align wheel selection with equipment capabilities and production objectives. Such bespoke service minimizes trial-and-error inefficiencies and lifts operational throughput.

- Wear Resistance: 30% increase vs. resinoid bond wheels

- Impact Toughness: Average endurance over 5 million impact cycles without microcracking

- Surface Finish Consistency: Maintains Ra ≤ 0.3 μm after prolonged use

- Cost Efficiency: Up to 20% reduction in total grinding cost over lifecycle