When tackling the challenges of grinding hard materials like gray cast iron, stainless steel, ceramics, or stone, selecting the right brazed diamond grinding wheel is pivotal. Not just a tool, your choice impacts production efficiency, precision, and cost-saving measures. This article guides you through the UHD high-performance brazed diamond grinding wheel technology, helping you align your grinding wheel selection with specific materials and operational demands.

Ever experienced rapid tool wear, reduced grinding efficiency, or compromised surface finish when working with tough or brittle materials? Issues like frequent wheel replacements, heat buildup, and inconsistent precision are typical pain points in industrial grinding. Such hurdles hamper production continuity and inflate operational costs, making it vital to seek solutions that extend tool life without sacrificing performance.

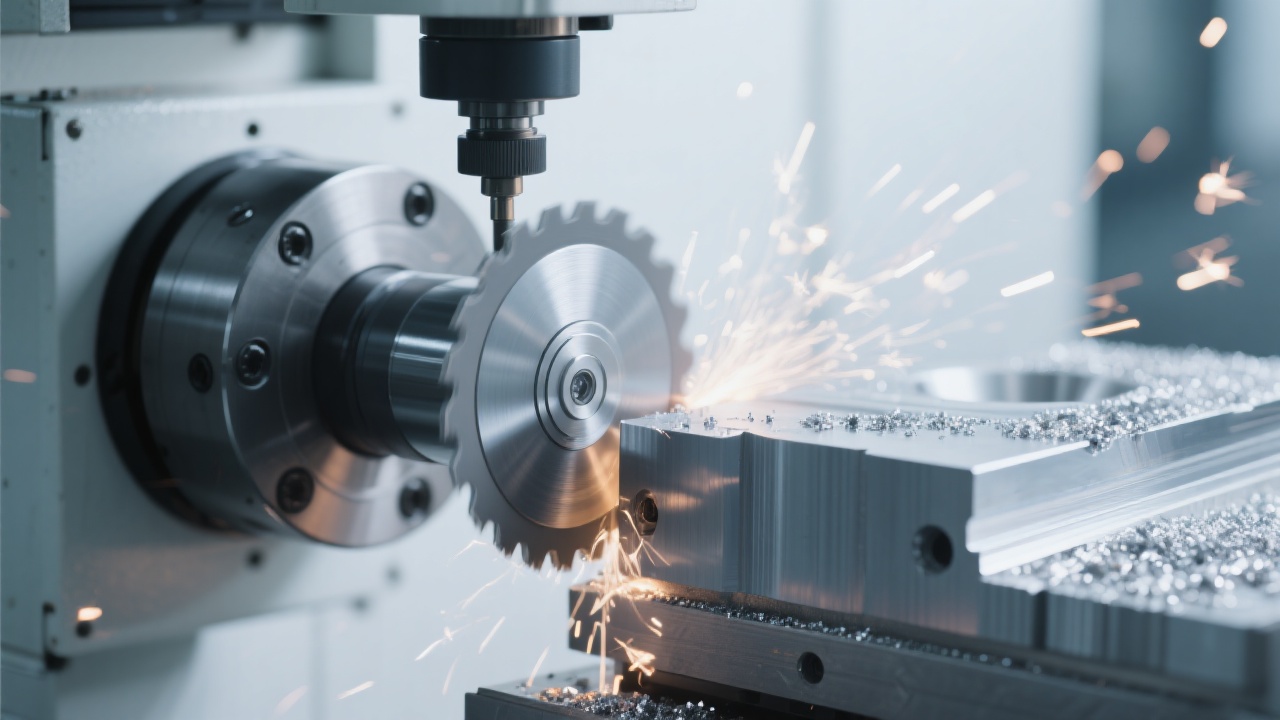

The UHD grinding wheel leverages an advanced brazing technology to secure superior-grade synthetic diamond grains directly onto the wheel’s matrix. This metal-bond method provides a remarkable combination of high wear resistance and robust impact strength. Unlike resin-bond wheels, UHD’s brazed bond supports higher grinding speeds and aggressive material removal rates while maintaining a stable wheel profile.

With a significantly enhanced thermal conductivity and mechanical bond, the UHD wheel reduces wheel glazing and chipping. This translates into up to 50% longer tool life compared to conventional bonded wheels and consistent grinding precision throughout the operation.

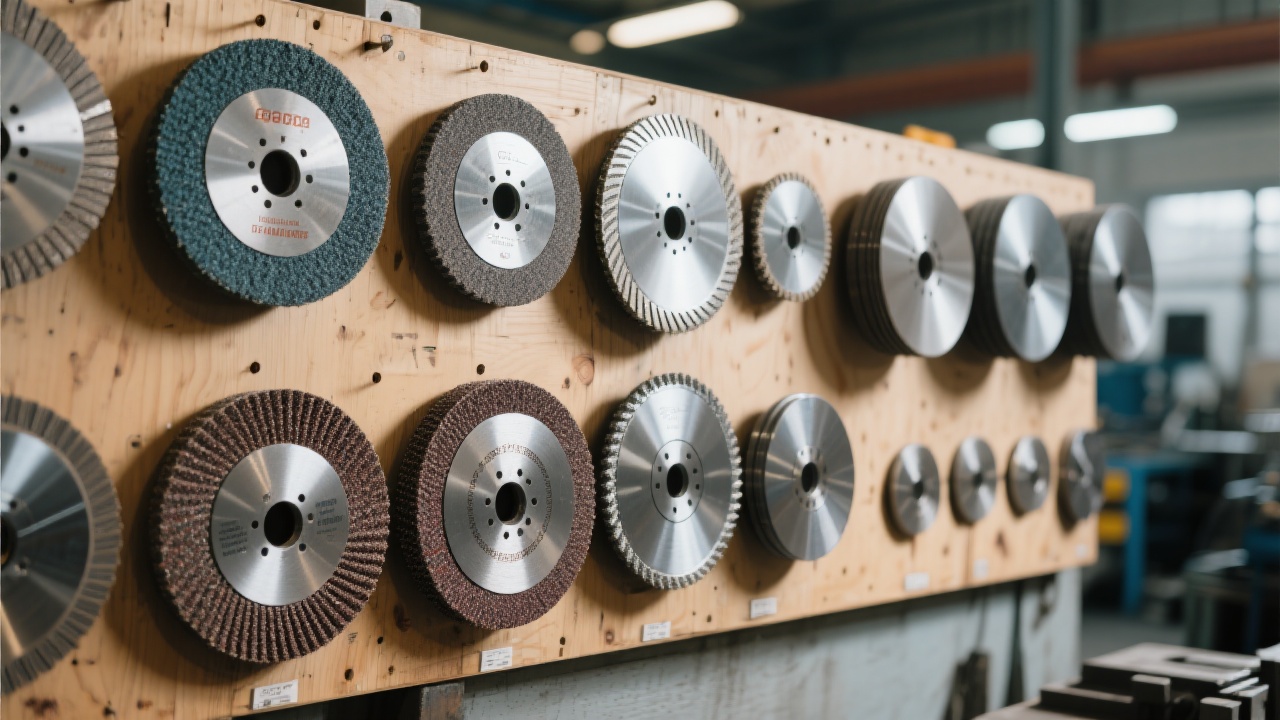

Selecting a UHD brazed diamond wheel isn’t one-size-fits-all. Each material demands a specialized wheel design to maximize grinding efficiency:

Industrial trials across multiple factories have documented UHD wheels achieving an impressive 30% boost in grinding efficiency and a doubling of tool lifespan versus traditional grinding wheels. Data from these tests reveal reduced downtime and lower consumables cost, accelerating ROI and cutting back on unscheduled maintenance.

| Grinding Wheel Type | Average Tool Life |

|---|---|

| Conventional Resin Bond | 40 Hours |

| UHD Brazed Diamond | 80 Hours |

UHD offers customization from diamond grit size to wheel diameter and surface finish, ensuring the grinding wheel suits your exact production specifications. Our one-stop solution streamlines ordering, from initial consultation to delivery, providing responsive support for surface treatment, sharpening, and performance optimization.

Every batch of UHD grinding wheels goes through rigorous ISO-certified quality control processes. Traceability reports and batch testing guarantee consistency in diamond distribution, bond strength, and dimensional accuracy. This adherence to international standards underpins your confidence in long-term operational reliability.

“Switching to UHD brazed diamond wheels reduced our tooling costs dramatically and stabilized our grinding consistency in high volume batches. The impact on our throughput was immediately noticeable.” – Senior Process Engineer, Automotive Part Manufacturer

Grinding hard materials can be complex—share your experience! Which materials have posed your biggest challenges? How did your previous grinding wheels rise (or fail) to the occasion? Your insight helps shape smarter solutions.