High diamond retention

Brazed bonding forms a metallurgical connection that holds abrasive particles more securely than many organic bonds. In practice, this often reduces premature grain loss and maintains consistent stock removal over longer runs.

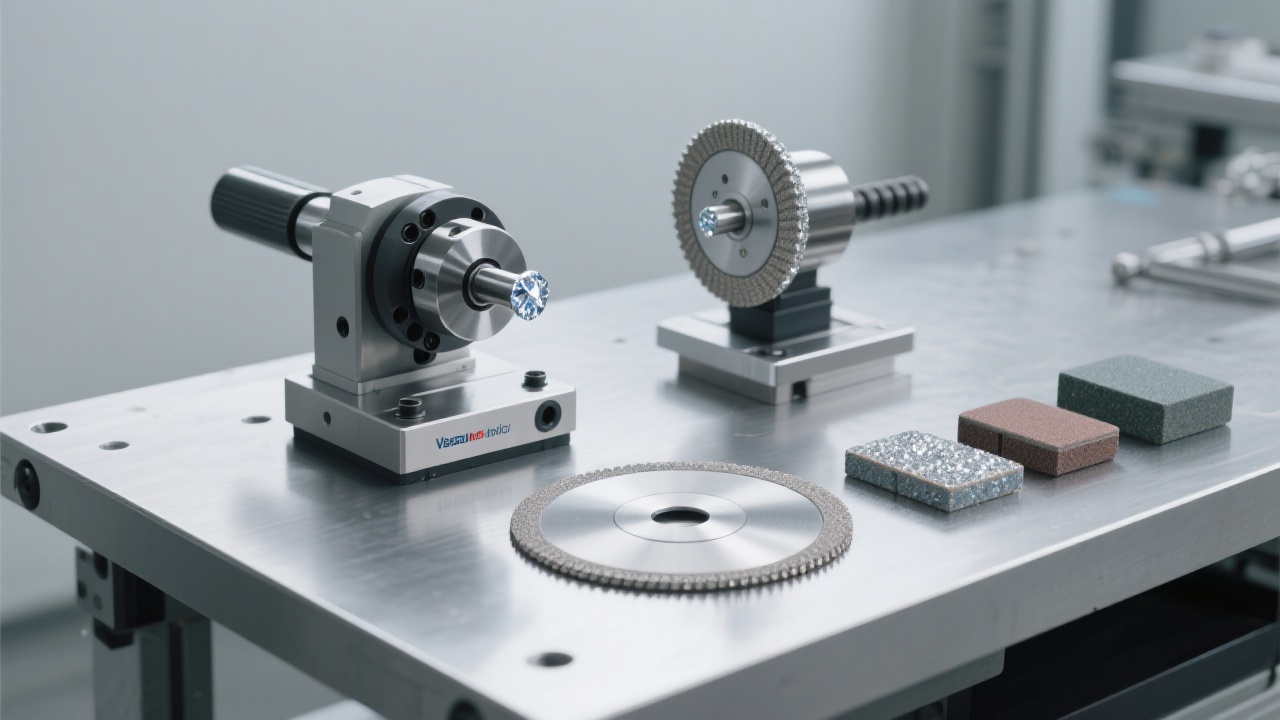

In hard-material grinding, the real bottleneck is rarely “power” or “speed”—it’s how long a wheel can hold sharp, intact diamonds under heat, shock, and uneven loading. UHD brazed diamond grinding wheels are engineered for exactly that: high wear resistance and impact performance that keep production stable when cutting gray cast iron, stainless steel, tungsten carbide, ceramics, and glass.

The result is more than a consumable upgrade: “Make every grinding pass more efficient and longer-lasting.” And in many plants, that translates into measurable OEE gains—not just nicer surface finish.

Conventional resin or vitrified systems can struggle in aggressive grinding: diamonds may pull out early, the bond may soften under heat, and edge chipping becomes a recurring headache. Brazed technology addresses these failure modes with a different logic: it aims to lock each diamond in place while keeping chip evacuation and cutting edges exposed.

Brazed bonding forms a metallurgical connection that holds abrasive particles more securely than many organic bonds. In practice, this often reduces premature grain loss and maintains consistent stock removal over longer runs.

With more diamond exposure, the wheel can “cut” rather than “rub,” helping lower friction heat and improve surface consistency—especially on hard-to-machine alloys and brittle materials.

In interrupted cuts, casting skin, or edge entry/exit conditions, impact resistance becomes decisive. A strong bond plus correctly selected diamond grade can reduce micro-fracture cascades and stabilize tool life.

Wear resistance is not only about “hardness.” It’s about maintaining effective cutting points while resisting grain pull-out. When diamonds stay anchored, the wheel keeps a stable cutting profile. If the abrasive population collapses early, the wheel starts to glaze and rub—raising heat, increasing power draw, and degrading surface finish.

In many industrial grinding lines, a well-matched brazed diamond wheel can deliver 2–5× longer usable life compared with general-purpose resin-bond wheels on similar hard-workpiece conditions, with 15–30% higher material removal rate (MRR) when process parameters and coolant strategy are optimized.

Impact doesn’t look dramatic—until it is. Intermittent contact, casting porosity, weld beads, or uneven fixtures create repeated shock loads that can crack diamonds, weaken bonding, and cause edge breakout. Impact-capable wheels rely on three controllable levers: diamond toughness, brazing integrity, and segment / rim geometry.

In field conditions with interrupted grinding, users often report 20–40% fewer edge-chipping incidents and significantly fewer unplanned wheel changes when moving from standard abrasive solutions to application-tuned brazed diamond wheels.

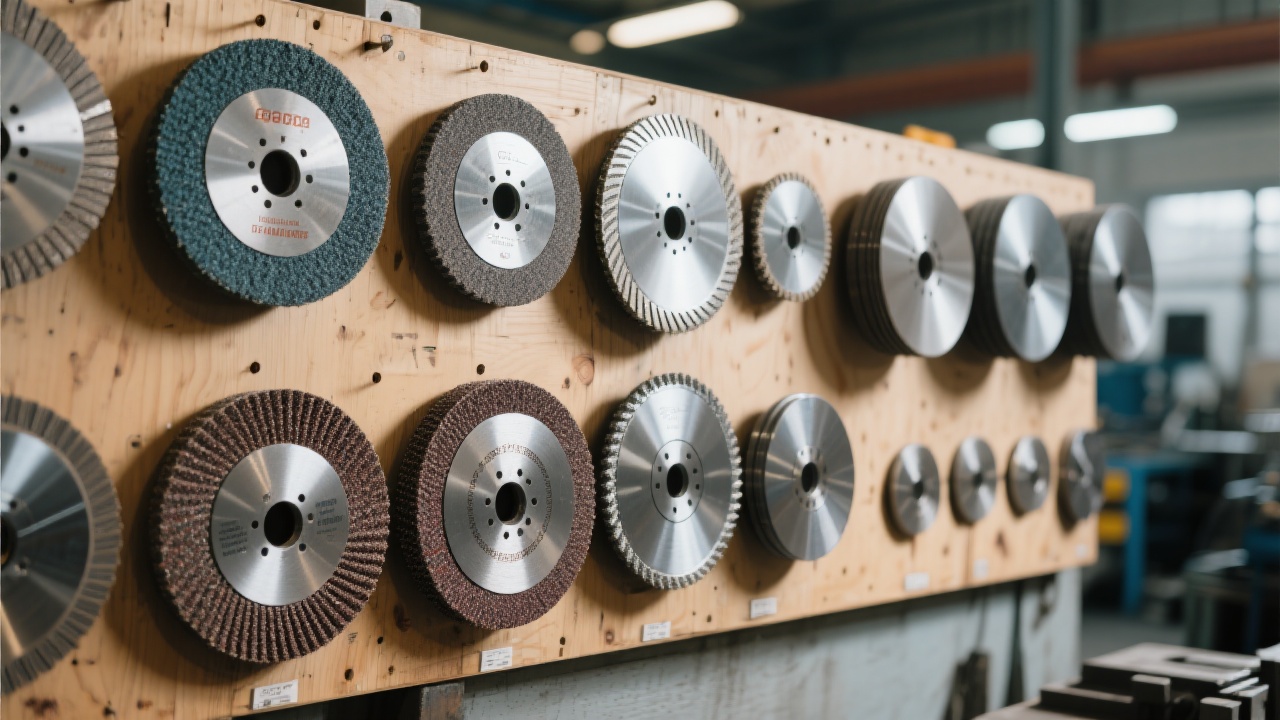

“Hard material grinding” is not one scenario. Gray cast iron behaves differently from stainless steel, and ceramics punish the wheel differently than glass. Selection must match the failure mode: loading, glazing, micro-chipping, thermal damage, or catastrophic grain loss.

Challenge: abrasive dust, intermittent surface skin, porosity, and impact at edges.

Solution focus: impact-tolerant diamond grade, stable brazed retention, and open chip flow to reduce clogging and heat.

Challenge: work-hardening, loading, and heat generation that can smear and glaze a wheel.

Solution focus: sharper exposure, optimized grit to keep cutting, and coolant-compatible design for thermal control.

Challenge: extreme hardness plus risk of thermal micro-cracks on precision surfaces.

Solution focus: consistent diamond retention and controlled aggressiveness to balance MRR and surface integrity.

Challenge: brittle fracture, chipping, edge breakout, and strict finish requirements.

Solution focus: finer grit strategies, stable rim geometry, and shock-reducing entry/exit behavior.

Below is a realistic benchmarking snapshot observed in industrial settings when switching from general-purpose wheels to application-matched brazed diamond grinding wheels. Exact outcomes vary by machine rigidity, coolant, operator method, and workpiece variability, but the pattern is consistent: less downtime, more stable output.

| Metric | Typical conventional wheel | UHD brazed diamond wheel (reference) |

|---|---|---|

| Usable tool life | Baseline (1.0×) | 2.0–5.0× |

| Material removal rate (MRR) | Baseline | +15% to +30% |

| Wheel changes per week | Frequent (process-dependent) | −20% to −50% |

| Edge chipping / breakouts | Higher risk on brittle parts | −20% to −40% |

| Process stability (scrap/rework) | Variable with wheel condition | More consistent output |

“The biggest difference wasn’t only the longer wheel life—it was the stability. Operators stopped chasing the process. Power draw stayed smoother, and the surface finish was more predictable across shifts.”

— Feedback commonly reported by production and maintenance teams after switching to brazed diamond solutions

Two wheels can look similar and still behave very differently at the spindle. What separates reliable performance from “good on paper” is process discipline: controlled incoming inspection of diamond quality, consistent brazing parameters, traceability, and final inspection aligned with an ISO quality management system.

For global buyers, customization is often where ROI becomes obvious. A small change in grit size, rim width, segment layout, or wheel diameter can significantly influence heat, finish, and cycle time—especially in automated lines.

Your workpiece type determines the best balance between wear resistance and impact performance. Are you grinding gray cast iron, stainless steel, tungsten carbide, ceramics, or glass?

Tell us your workpiece material and process goal (higher MRR, better finish, fewer chips, or longer wheel life). A precise match is often the fastest way to unlock gains—because this is not just a tool, but your production partner.

Whether you need aggressive stock removal on hard alloys or chip-controlled grinding on brittle ceramics, the fastest path is an application-tuned wheel specification. Make every grinding pass more efficient and longer-lasting—with a wheel built around your material, machine, and finish target.

Request a Custom UHD Brazed Diamond Grinding Wheel RecommendationTypical inputs: material, grit preference, wheel size, coolant method, target finish, and current pain points (loading, glazing, chipping, burn).