Anti-impact design logic

Higher retention strength plus controlled exposure height reduces sudden grit loss and minimizes localized collapse, keeping the wheel “true” longer.

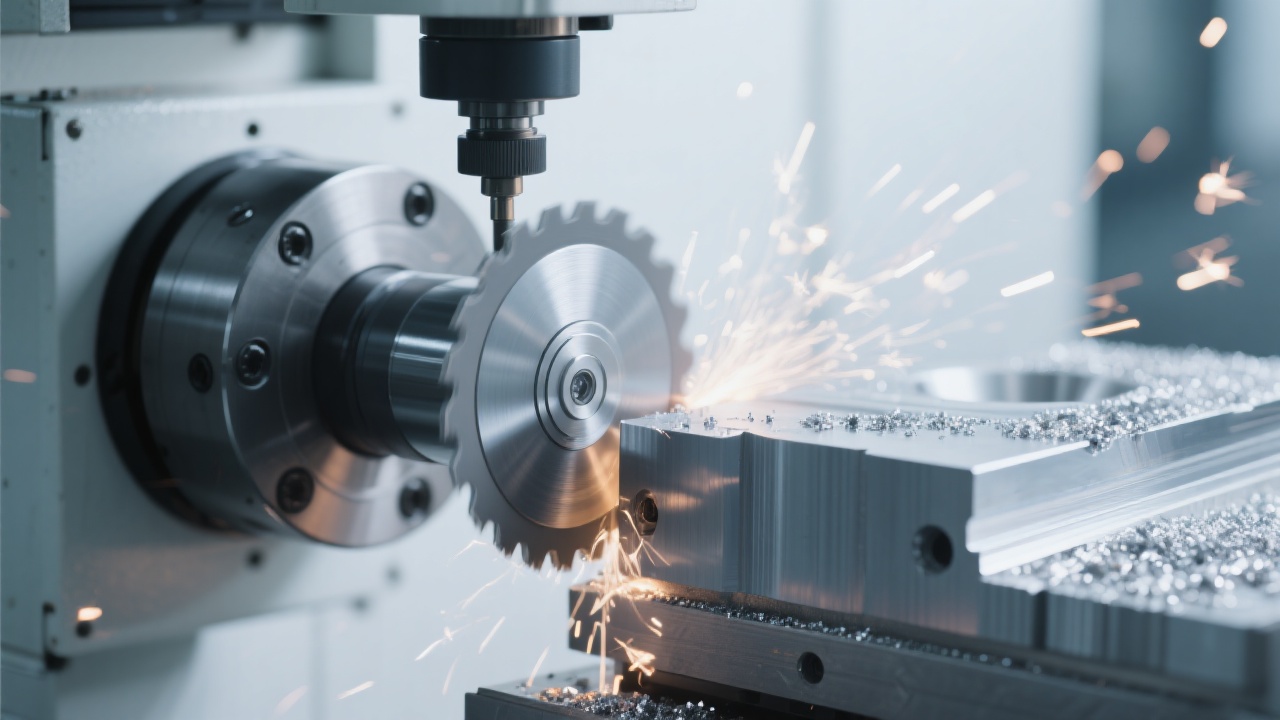

In high-load industrial grinding, the “real” cost of a wheel is rarely the purchase itself—it’s the downtime, inconsistent surface finish, and the hidden yield loss caused by premature wear or segment failure. UHD-grade brazed diamond grinding wheels are engineered for that reality: precise, efficient, and durable performance under demanding conditions.

Traditional bonding methods can struggle when the application combines high peripheral speed, cyclic shock loads, and hard-to-grind materials. Brazing addresses a core failure mode: grit pull-out. In a brazed diamond grinding wheel, diamond particles are metallurgically joined to the wheel body through a brazing alloy, producing a strong bond that holds up under shear and impact forces.

Technical note: In many heavy-duty grinding lines, grit retention is the dominant factor behind stable cutting ability. Stronger retention typically translates into a longer “effective sharpness window,” reducing the frequency of dressing or wheel changes.

For UHD brazed designs, performance is not only about “strong bonding.” It is a system-level match between: diamond grade (toughness and thermal stability), grit size distribution (chip space and load sharing), and brazed layer geometry (exposure height and support angle). When optimized together, a wheel can remain aggressively cutting without collapsing into rapid wear.

| Design Variable | What It Controls | Practical Result in Grinding |

|---|---|---|

| Diamond grit toughness & purity | Fracture resistance and thermal degradation | More stable cutting edges, longer tool life |

| Grit size distribution (single vs. mixed) | Chip evacuation, contact mechanics | Lower loading risk, smoother energy curve |

| Brazed alloy and wetting behavior | Bond strength and grit retention consistency | Reduced grit pull-out under shock |

| Diamond exposure height (controlled) | Sharpness vs. support | High MRR without premature segment breakage |

Industrial grinding rarely happens in a “lab-perfect” environment. Workpieces vary, operators adjust pressure, and machines introduce micro-vibrations. An impact-resistant brazed design helps maintain cutting stability when conditions fluctuate—especially in applications where the wheel meets discontinuous surfaces, edges, holes, or intermittent contact.

Higher retention strength plus controlled exposure height reduces sudden grit loss and minimizes localized collapse, keeping the wheel “true” longer.

Proper diamond selection and brazing consistency help preserve cutting points, reducing glazing and maintaining predictable power draw.

Effective on many high-hardness substrates where conventional abrasives wear too fast, enabling higher throughput and fewer tool changes.

Actual results depend on material, machine rigidity, coolant strategy, and operator parameters. The following ranges are common reference points observed in heavy-duty grinding when upgrading from lower-retention solutions to UHD brazed diamond wheels:

| Metric | Typical Range | Operational Meaning |

|---|---|---|

| Tool life extension | 1.8× to 4.0× | Fewer wheel changes, more uptime |

| Material removal rate (MRR) | +15% to +45% | Higher throughput at stable surface quality |

| Wheel consumption per part | -20% to -55% | Lower cost-per-piece, less process variability |

| Unplanned stops caused by segment failure | -30% to -70% | More predictable scheduling |

Why ranges matter: If a plant’s pain point is downtime, the most meaningful KPI may be “wheel changes per shift.” If it’s heat marks or chipping, focus on process stability (power draw trend + finish consistency).

B2B buyers do not only evaluate a brazed diamond wheel by its first run. They evaluate whether the next shipment behaves the same. That is where an ISO-aligned quality management system becomes practical value: it reduces batch-to-batch variation and makes performance reproducible.

1) Incoming inspection

Diamond grit verification, metal substrates, traceability.

2) Brazing parameter control

Temperature curve, time, alloy consistency, fixture stability.

3) In-process checks

Grit distribution, exposure uniformity, runout checks.

4) Final inspection

Balance, dimensional tolerance, visual integrity, packaging protection.

Buyer takeaway: A documented process is not paperwork—it’s repeatability. For production lines, repeatability is often worth more than a one-time performance peak.

In real procurement, the most common mismatch is not “diamond vs. non-diamond.” It is an incomplete parameter match: the wheel is good, but the grit size, exposure profile, or body geometry is not aligned with the line’s objectives. A practical customization workflow begins with measurable targets and ends with controlled production parameters.

Challenge: Intermittent contact and edge impacts caused segment micro-chipping and inconsistent finish. The line also faced frequent pauses for wheel changes.

Customization focus: Increase impact tolerance and stabilize cut: adjust diamond toughness grade, optimize grit mix for chip space, and control exposure height to balance sharpness and support.

Observed reference outcome: In similar industrial conditions, plants commonly report 20–35% fewer wheel-related stops and ~25% higher throughput after parameter stabilization.

“After switching to the optimized brazed diamond wheel, the cutting behavior became more predictable. We saw fewer sudden spikes in power draw and less rework caused by surface inconsistency.”

— Production Engineer, high-intensity grinding line (feedback excerpt)

For buyers evaluating high wear-resistant, impact-resistant diamond wheels at the awareness stage, the most effective approach is to translate the application into parameters. The goal is not theoretical perfection—it is reliable performance with measurable productivity gains.

Start with conservative feed and step up gradually while monitoring power draw. Avoid sudden aggressive engagement on sharp edges when possible; impact events are where retention strength is tested most.

Maintain consistent coolant delivery and keep the wheel face clean. In many lines, loading (not wear) is the hidden cause of efficiency loss—especially when chip evacuation is constrained.

Share your material, machine model, and target KPI. A technical proposal can map grit, exposure, and brazing parameters to your real operating conditions—so the wheel you receive performs like the wheel you tested.

Request a Customized UHD Brazed Diamond Grinding Wheel RecommendationTypical response time: within 24–48 business hours for initial parameter review.